3D scanners

3D scanners utilize various innovations to produce a 3D design. Examples are time-of-flight, structured/ regulated light, volumetric scanning and a lot more.Just recently, business like Microsoft and Google allowed their hardware to carry out 3D scanning, for instance, Microsoft's Kinect. Soon digitizing genuine things into 3D designs will end up being as simple as taking an image. Future variations of smart devices will most likely have incorporated 3D scanners.

Presently, costs of 3D scanners vary from pricey expert commercial gadgets to $30 Do It Yourself scanners anybody can make in the house.

View more information: Best 3d Printer Under 1000

3D modeling software application

3D modeling software application likewise is available in lots of types. There's the commercial grade software application that costs thousands a year per license, however likewise complimentary open source software application, like Mixer, for example. You can discover some newbie video tutorials on our Mixer tutorials page.When you are a novice, and some options are a bit frustrating, we advise beginning with Tinkercad. Tinkercad has a totally free variation, and it operates in internet browsers that support WebGL, for example, Google Chrome. They provide novice lessons and has an integrated into choice to obtain your item printed through numerous 3D printing services.

When you have a 3D design, the next action is to prepare it to make it 3D.

From 3D design to 3D printer

You will need to prepare a 3D design before it is all set to be 3D printed. This is exactly what they call slicing. Slicing is dividing a 3D design into hundreds or countless horizontal layers and has to be made with the software application.Often a 3D design can be sliced from within a 3D modeling software application. It is likewise possible that you are required to utilize a specific slicing tool for a particular 3D printer. When the 3D design is sliced, you are all set to feed it to your 3D printer. This can be done through USB, SD or wifi. It depends upon exactly what brand name and type 3D Printer you have. When a file is submitted to a 3D printer, the things is prepared to be 3D printed layer by layer. The 3D printer checks out every piece (2D image) and develops a three-dimensional item.

View more information: How Much Does A 3d Printer Cost

Beginning with 3D Printing

Beginning with the 3D printing implies asking yourself exactly what you wish to discover very first. Do you think about the hardware, or do you , to concentrate on developing things?We have produced 3D printers for newbies purchasers overview of assist you choose if you must select a pre-assembled 3D Printer or a 3D printer package.

In case you have a tight spending plan, and you wish to begin your journey into finding out 3D printing, inexpensive 3D printer sets can be a fantastic starting point. If you have an interest in going this path, please read our short article about inexpensive 3D printer sets. This post describes exactly what to try to find when you're comparing these packages.

Various kinds of 3D Printing Technologies and Processes

Not all 3D printers utilize the very same innovation. There are numerous methods to print, and all those readily available are additive, generally varying in the method layers are develop to produce the last things.Some approaches utilize melting or softening product to produce the layers. Selective Laser Sintering (SLS) and Merged Deposition Modeling (FDM) are the most typical innovations utilizing by doing this of 3D printing. How Do 3d Printers Work aAnother technique is when we discuss treating a photo-reactive resin with a UV laser or another comparable source of power one layer at a time. The most typical innovation utilizing this technique is called Stereolithography (SLA).

View more information: Black Friday 3d PrinterTo be more exact: given that 2010, the American Society for Screening and Products (ASTM) group "ASTM F42-- Additive Production", established a set of requirements that categorize the Additive Production procedures into seven classifications inning accordance with Requirement Terms for Ingredient Production Technologies. These seven procedures are:

Barrel Photopolymerisation

A 3D printer based upon the Barrel Photopolymerisation technique has a container filled with photopolymer resin which is then solidified with a UV light. Stereolithography (SHANTY TOWN).The most typically utilized innovation in this procedures is Stereolithography (SLA). This innovation uses a barrel of liquid ultraviolet treatable photopolymer resin and an ultraviolet laser to develop the things' layers one at a time.

For each layer, the laser beam traces a cross-section of the part pattern on the surface area of the liquid resin. Direct exposure to the ultraviolet laser light remedies and strengthens the pattern traced on the resin and joins it to the layer listed below.

After the pattern has been traced, the SLA's elevator platform comes down by a range equivalent to the density of a single layer, generally 0.05 mm to 0.15 mm (0.002 ″ to 0.006 ″). Then, a resin-filled blade sweeps throughout the cross-section of the part, re-coating it with fresh product. On this brand-new liquid surface area, the subsequent layer pattern is traced, signing up with the previous layer.

The total three-dimensional things are formed by this task. Stereolithography needs making use of supporting structures which serve to connect the part to the elevator platform and to hold the item because it drifts in the basin filled with liquid resin. These are eliminated by hand after the item is completed.

This strategy was created in 1986 by Charles Hull, who likewise at the time established the business, 3D Systems.

View more information: Types Of 3d Printers

Constant Liquid User interface Production (CLIP).

Other innovations utilizing Barrel Photopolymerisation are the brand-new ultrafast Constant Liquid User interface Production or CLIP and partially utilized older Movie Transfer Imaging and Solid Ground Treating.Product Jetting.

In this procedure, the product is used in beads through a little size nozzle, much like the method a typical inkjet paper printer works. However, it is utilization layer-by-layer to a develop platform making a 3D item then solidified by UV light.Binder Jetting.

With binder jetting two products are utilized: powder base product and a liquid binder. In the construct chamber, the powder is spread out in equivalent layers, and the binder is used through jet nozzles that "glue" the powder particles in the shape of a configured 3D item. The completed things are "glued together" by binder stays in the container with the powder base product. After the print is ended up, the staying powder is wiped and utilized for 3D printing the next item. This innovation was very first established at the Massachusetts Institute of Innovation in 1993 and in 1995 Z Corporation got a special license.The following video reveals a high-end binder jetting based 3D printer, the ExOne M-Flex. This 3D printer utilizes metal powder and treating after the binding product is used.

Product Extrusion.

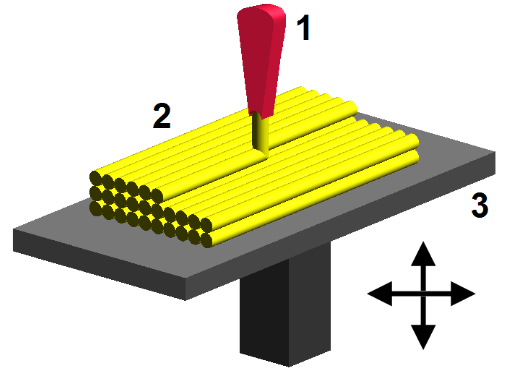

The most frequently utilized innovation in this procedure is Merged Deposition Modeling (FDM).Merged Deposition Modeling (FDM).

The FDM innovation works utilizing a plastic filament or metal wire which is unwound from a coil and providing product to an extrusion nozzle which can turn the circulation on and off. The nozzle is heated up to melt the product and can be relocated both horizontal and vertical instructions by a numerically regulated system, straight managed by a computer-aided production (CAMERA) software application bundle. How Do 3d Printers Work

The item is produced by extruding melted product to form layers as the product solidifies right away after extrusion from the nozzle. This innovation is most commonly utilized with two plastic filament product types: ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic acid). Though lots of other products are offered to vary in homes from wood fill to versatile as well as conductive products.

FDM was created by Scott Crump in the late 80's. After patenting this innovation, he began the business Stratasys in 1988. The software application that features this innovation immediately produces assistance structures if needed. The device gives two products, one for the design and one for a nonreusable assistance structure.

The term merged deposition modeling, and its abbreviation to FDM are trademarked by Stratasys Inc

Merged Filament Fabrication (FFF).

The precisely comparable term, Merged Filament Fabrication (FFF), was created by the members of the RepRap task to offer an expression that would be lawfully unconstrained in its usage.Various kinds of FFF 3D Printers.

There are various kinds of FFF 3D printers. They vary in mechanical plans and coordinate systems. A Cartesian coordinate system is for example completely various from a Delta coordinate system, however even within the Cartesian coordinate system, there are different mechanical plans. Check out whatever about it in our finest 3D printers guide.Powder Bed Blend.

The most typically utilized innovation in this procedures is Selective Laser Sintering (SLS).Selective Laser Sintering (SLS).

SLS utilizes a high power laser to fuse little particles of plastic, metal, ceramic or glass powders into a mass that has the wanted three-dimensional shape. The laser selectively merges the powdered product by scanning the cross-sections (or layers) produced by the 3D modeling program on the surface area of a powder bed. After each cross-section is scanned, the powder bed is reduced by one layer density. Then a brand-new layer of product is used on top, and the procedure is duplicated up until the things are finished.All unblemished powder stays as it is and ends up being an assistance structure for the item. For that reason, there is no requirement for any assistance structure which is a benefit over SLS and SHANTY TOWN. All unused powder can be utilized for the next print. SLS was established and patented by Dr. Carl Deckard at the University of Texas in the mid-1980s, under the sponsorship of DARPA.

Sheet Lamination.

Sheet lamination includes a product in sheets which are bound together with external force. Sheets can be metal, paper or a kind of the polymer. Metal sheets are bonded together by ultrasonic welding in layers, and after that CNC grated into a correct shape. Paper sheets can likewise be utilized. However, they are glued by adhesive glue and cut in shape by accurate blades. A leading business in this field is Mcor Technologies.Examples & applications of 3D printing.

How Do 3d Printers Work Applications consist of quick prototyping, architectural scale designs & maquettes, health care (3D printed prosthetics and 3D printing with human tissue) and home entertainment (e.g. film props).Other examples of 3D printing would consist of rebuilding fossils in paleontology, reproducing ancient artifacts in archaeology, rebuilding bones and body parts in forensic pathology and rebuilding greatly broken proof gotten from criminal offense scene examinations.

3D printing market.

The around the world 3D printing market is anticipated to grow from $3.07 B in earnings in 2013 to $12.8 B by 2018, and go beyond $21B in around the world income by 2020. As it progresses, 3D printing innovation is predestined to change nearly every significant market and alter the method we live, work, and play in the future.Source: Wohlers Report 2015.

Medical market.

The outlook for the medical usage of 3D printing is developing at an exceptionally quick rate as professionals are starting to make use of 3D printing in advanced methods. Clients all over the world are experiencing the enhanced quality of care through 3D printed implants and prosthetics never before seen.

Bio-printing.

Since the early two-thousands, 3D printing innovation has been studied by biotech companies and academic community for possible usage in tissue engineering applications where organs and body parts are constructed utilizing inkjet strategies. Layers of living cells are transferred onto a gel medium and gradually developed to form 3 dimensional structures. We describe this field of the research study with the term: bio-printing.Aerospace & air travel markets.

The development in the utilisation of 3D printing in the aerospace and air travel markets can, for a big part, be stemmed from the advancements in the metal additive production sector.NASA for the utilizing selective laser melting and since March 2015 the FAA cleared GE Air travel's very first 3D printed jet engine part to fly: a laser sintered real estate for a compressor inlet temperature level sensing unit.

Automotive market.

Although the vehicle market was amongst the earliest adopters of 3D printing, it has actually for years relegated 3D printing innovation to low volume prototyping applications.Nowadays using 3D printing in the automobile is progressing from fairly easy idea designs for fit and surface checks and style confirmation, to practical parts that are utilized in test lorries, engines, and platforms. The expectations are that 3D printing in the vehicle market will produce a combined $1.1 billion dollars by 2019.

Industrial 3D Printing.

In the last few years the term 3D printing has ended up being more recognized, and the innovation has reached a wider public. Still, many people have not even become aware of the term while the innovation has remained in usage for years. Particularly producers have long utilized these printers in their style procedure to develop models for conventional production and research study functions. Utilizing 3D printers for these functions is called fast prototyping.Why utilize 3D printers in this procedure you may ask yourself. Now, quick 3D printers can be purchased for 10s of countless dollars and wind up conserving the business lot of times that quantity of loan in the prototyping procedure. How Do 3d Printers Work For instance, Nike utilizes 3D printers to produce multi-colored models of shoes. They utilized to invest countless dollars on a model and wait weeks for it. Now, the expense is just in the numerous dollars, and modifications can be made immediately on the computer system, and the model reprinted on the very same day.

Besides quick prototyping, 3D printing is likewise utilized for fast production. Quick production is a brand-new technique of making where business is utilizing 3D printers for brief run custom-made production. In this method of producing the printed things are not models however the real end user item. Here you can anticipate more schedule of personally personalized items.

Individual 3D printing.

Individual 3D printing or domestic 3D printing is primarily for enthusiasts and lovers and began growing in 2011. Because of quick advancement within this brand-new market printers are getting more affordable and less expensive, with rates usually in the variety of $250-- $2,500. This puts 3D printers into a growing number of hands.The RepRap, open source task, sparked this enthusiast market. For about a thousand dollars individuals might purchase the RepRap package and assemble their desktop 3D printer. Everyone dealing with the RepRap shares their understanding so other individuals can utilize it and enhance it once again.

History.

In the history of production, subtractive approaches have typically preceded. The province of machining (producing specific shapes with high accuracy) was a subtractive affair, from filing and turning through milling and grinding.Additive production's earliest applications have been on the Toolroom end of the production spectrum. For instance, quick prototyping was among the earliest additive variations and its objective was to lower the preparation and expense of establishing models of brand-new parts and gadgets, which was earlier just made with subtractive toolroom approaches (normally gradually and expensively). Nevertheless, as the year's pass and innovation constantly advance, additive techniques are moving ever even more into the production end of production. Parts that previously were the sole province of subtractive approaches can now sometimes be made more beneficially through additive ones.

Nevertheless, the genuine combination of the more recent additive innovations into business production is a matter of matching subtractive techniques instead of displacing them totally. Forecasts for the future of industrial production, beginning with today's currently- started infancy duration, are that production companies will have to be versatile, ever-improving users of all offered innovations to stay competitive.

Future.

It is forecasted by some additive production supporters that this technological advancement will alter the nature of commerce since end users will have the ability to do much of their production instead of participating in the trade to purchase items from other individuals and corporations.3D printers efficient in outputting in color and several products currently exist and will continue to enhance to a point where practical items will have the ability to be output. With impacts on energy usage, waste decrease, modification, item accessibility, medication, art, building and construction and sciences, 3D printing will alter the production world as we understand it.

If you have an interest in more future forecasts relating to 3D printing, have a look at The Future Of Open Fabrication.

Solutions.

Not everyone can manage or wants to purchase their 3D printer. Does this suggest you can not take pleasure in the possibilities of 3D printing? No, not to fret. There are 3D printing service bureaus like Shapeways, Ponoko and Sculpteo that can extremely cheaply print and provide things from a digital file that you just publish to their site. You can even offer your 3D styles on their site and make a little loan out of it!There is likewise business who use their services business-to-business. When, for example, you have an architecture practice, and you have to develop design scales, it is lengthy doing this the old made method. There are services where you can send your digital design to, and they print the structure on the scale for you to utilize in customer discussions. This sort of services can currently be discovered in a lot of various markets like oral, medical, home entertainment and art.